Compatibility

Methanol was the primary alternative fuel considered for transport sector in 1970s and 1980s to reduce dependence on fossil oil. Methanol was used as a transportation fuel until the mid-1990s in North America and Europe. In China’s transportation fuel pool, various methanol blends ranging from M5 to M100 are used. In China, mass production of methanol vehicles is capable of producing up to 500,000 engines for M100. Methanol-blended fuels are explored also by many other countries, for example Denmark (Task 56 report).

Methanol can be used as low or high concentration blends for road transport and marine applications, with conventional or special engine technologies (Table 1). AMF Task 56 report presents in detail methanol use options for different transport sectors. Here a condensed view is given,

Table 1. Methanol engine concepts (Schröder et al. 2020).

|

Engine type |

Mode |

Fuel |

Transport sector |

|

Spark ignition (SI) |

Port fuel injection (PFI) Direct injection (DI) Direct injection (DI lean) |

M0 to M85, GEM, MTBE* |

PC, LDV, HDV |

|

Compression ignition (CI) |

Dual fuel (DF) |

M0-M50 |

HDV, Marine |

|

Direct injection (DI) |

M100, MD95, FAME* |

HDV, Marine |

|

|

New concepts (HCCI, PPC) |

M100 |

HDV, Marine |

|

|

Fuel cell (FC) |

|

M100 |

PC, LDV, HDV, Marine |

*Fuel components produced from methanol

Fuel properties of methanol resemble more gasoline than diesel (see fuel properties section). However, methanol blending in gasoline is limited to low concentrations for use in conventional SI engines, for example in Europe and North America, up to a few percentages. Infrastructure and cars are not designed for methanol use in these regions. Methanol is compatible with conventional gasoline in a form of ether, MTBE. Due to high octane rating of methanol, it is used for race cars and for some other specialty engine applications.

High methanol concentrations, e.g. M85, is used in special Flexible Fuel Vehicles (FFVs), which were first developed for methanol and later optimized for ethanol. Mid-level (A20-A30) and high-level alcohol fuels are high octane fuels that would allow automakers to optimize cars with higher engine compression ratios, downsized engines, increased turbocharging, and enhanced direct injection. High engine efficiency could compensate for methanol’s low energy density. Bromberg and Cheng (2010) have highlighted the potential of directly injected spark ignited engines for heavy-duty vehicles.

In AMF Task 44 (Fanand Donglian 2017), methanol blends (M15 and M30) were studied in comparison with neat gasoline using two PFI and two GDI vehicles. The tests were conducted at normal (25℃) and at low ambient temperatures (-7℃). Also ethanol blends were studied, but those results are not referred here. Many emission components were high during the first acceleration, but reduced to nearly zero as the catalyst lighted off. In both test temperatures, hydrocarbons (HC), carbon monoxide (CO) and methane emissions decreased slightly as the alcohol proportion of fuel increased, while nitrogen oxides (NOX) increased slightly. Tailpipe CO2 did not change substantially. Unburned methanol, formaldehyde and acetaldehyde emissions increased proportionally with the increasing alcohol content, while benzene, toluene, ethylene, propylene, 1,3-butadiene and isobutene decreased slightly. In the evaporative emission tests, only slight differences in the HC emissions were observed between M15 and gasoline.

In the earlier work, increasing methanol content of fuel has reduced CO, HC and NOx when compared to gasoline, while formaldehyde emissions have increased, especially at cold-starts (Bromberg and Cheng 2010, Bechtold et al. 2007 and Ohlström et al. 2001).

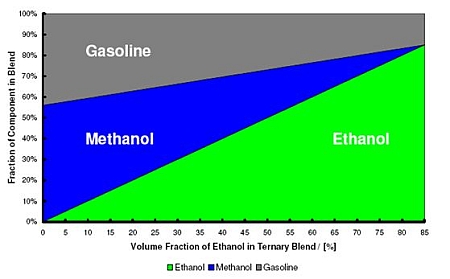

In some markets, the focus is on blends of gasoline, ethanol and methanol (GEM). In this concept, ethanol is serving as a co-solvent for methanol. These tri-component blends have constant air-to-fuel ratio of 9.7:1, which is same ratio as air-to-fuel ratio for E85 fuel (Figure 1). Behaviour of virtual and physical alcohol sensors used in the FFVs have been studied with GEM blends, as well as performance of cars at cold temperatures, emissions and costs. The results indicate that GEM blends could be used in FFV cars as a drop-in alternative to E85 fuel (Turner et al. 2012).

Figure 1. Gasoline, ethanol, methanol blends (GEM) with air-to-fuel ratio equivalent to conventional E85 fuel. (Turner et al. 2012).

Fuel properties of methanol do not resemble those of diesel fuel, for example, cetane number of methanol is extremely low. However, there are options to use methanol in CI engines. One option to use methanol in conventional diesel engines in to convert it to Fatty Acid Methyl Esters (FAME). Other options cover adding an ignition enhancer to methanol, so called MD95 concept and dual-fuel methanol diesel engine concept. Other options are described by Schröder et al. (2020).

A concept of adding an ignition enhancer to methanol was studied in AMF Task 46 (Nylund et al. 2016) using Scania ethanol engine and additized methanol and later in SUMMETH project for marine sector (Aakko-Saksa 2020). This engine concept proved to operate quite well with additive treated neat methanol. However, with these methanol fuels the engine didn’t reach full power, and the injection periods on partial load were prolonged compared to ethanol operation. Methanol increased the particulate matter (PM) emissions, which was thought to be an indication of semivolatile components or artifacts as methanol contains no soot forming carbon-to-carbon bonds. The standard oxidation catalyst most probably would have reduced this PM with methanol. A blend of 70 % ethanol and 30 % methanol delivered lower CO, HC and NOx emissions compared to the baseline ethanol fuel. However, it must be stated that Scania doesn’t approve the use of methanol fuels.

In marine sector, methanol is regarded as promising marine fuel alternative (Moirangthem 2016, Ellis and Tanneberger 2015). Also engines for methanol use in marine sector are available. Wärtsilä has developed a methanol-diesel retrofit concept, a dual-fuel technology, which has the advantage of using diesel as a back-up fuel. Common rail system for methanol injection, cylinder heads, fuel injectors and changes in fuel pumps are needed, amongst others. (Haraldson 2013). This concept is demonstrated in Stena Germanica in Sweden. MAN has developed a methanol engine technology that is used in seven 50,000 dwt tankers by Waterfront Shipping in Canada. The alternatives for marine sector were discussed in the AMF Task 41 (McGill et al. 2013).

Development is ongoing on partially premixed combustion (PPC), in which lowered combustion temperature limits NOX formation and enables high efficiency when using 100% methanol without ignition enhancer (Schröder et al. 2020).