Production, distribution and storage

Fossil methane is natural gas trapped beneath the surface of the earth into the different geological formations made of layers of sedimentary porous rock, topped by an impermeable formation that acts as a roof. The gas is extracted by drilling through the impermeable rock and the gas released is usually under pressure. After extraction NG must go through some processes, basically, to eliminate oil, water, and some other trace components from the raw extracted gas. Today unconventional sources of fossil methane are also important: 1) Shale gas is a form of natural gas trapped into shales, which are fine-grained and organic-rich rock formations. The estimation of its potential and existing reserves has substantially changed along with the progress in extraction technology, the hydraulic fracturing and the horizontal drilling techniques. 2) Coal-bed gas is a form of natural gas that found in a near-liquid state adsorbed into a solid matrix of coal. Free of H2S, coal-bed gas contains lower amounts of heavier hydrocarbons such as ethane, propane, and butane than conventional natural gas. 3) Tight gas (or tight sandstone gas) trapped within impermeable rock and non-porous sandstone or limestone formations. Thus, its extraction is complicated. 4) Methane hydrates are solid compounds trapped within a crystal water structure, forming a solid structure similar to ice. Substantial reserves of methane hydrates have been found, but commercial-scale production of gas from these formations has not been accomplished..

The term "biomethane" refers to methane from a renewable origin. It is produced by the anaerobic digestion of organic matter (dead animal and plant material, manure, sewage sludge, organic waste, etc.), which is stored in air-tight tanks in order to reproduce the best possible conditions for the anaerobic microbes producing gas during the digestion process. It can also be produced by anaerobic degradation of organic matter in landfills, and this is referred as landfill gas. The raw gas is known as biogas, mainly consisting of methane and CO2 plus some minor trace components which greatly depend on the feedstock. Biomethane is known as the upgraded form of biogas, and its final quality/composition is dependent on the operational parameters of the final use, and on the upgrading technology used. I.e. biomethane is a methane-rich gas derived from biogas. The third route to biomethane is via gasification of biomass. A great benefit of biogas/biomethane is that it can be produced from a great variety of sources: basically, all types of biomatter can be used for this purpose, such as waste. However, not all substrates behave in the same way regarding the biogas production efficiency or have the same emissions saving potential. Since methane is the main constituent of natural gas, biomethane can be used in natural gas vehicles without need for modifications.

Biomethane can be produced locally and therefore distribution is different from natural gas in many respects. However, both bio-origin and fossil methane is used in compressed or liquefied state for storage and for transportation purposes.

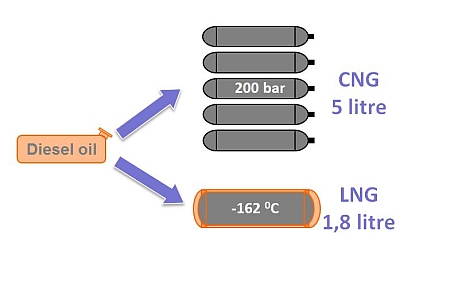

- Compressed methane (CNG, CBG): natural gas or biomethane has been compressed after processing; mainly used for vehicles and typically compressed up to 200 bar.

- Liquefied methane (LNG, LBG): natural gas or biomethane has been liquefied after processing. Temperature is about -161.7 °C at atmospheric pressure and, when used as an automotive fuel, it can be stored in on-board cryogenic tanks (vacuum-isolated stainless-steel vessels), which have different operating pressure ranges.

Natural gas is transported over long distanced as compressed by pipeline or as liquefied by ships. Natural gas pipeline pressures in Europe typically range from 2 to 80 bar. The trend nowadays is to increase the pressure in the international connecting pipelines in order to reduce the transport cost. Pressure of the pipelines laid down at the bottom of the sea has to be sufficient, as it is not possible to install intermediate compression stations. Natural gas is transported as liquefied by ship, for example, when the distances to the consumption point are long (above 4.000 km), for example, when transporting large volumes over the seas. Usually most of the LNG gets gasified and injected into the NG grid. However, part of it can be directly used as LNG, and then usually transported by LNG road tankers.

Gaseous and liquefied natural gas pathways canot be clearly separated from each other, as many of the imported LNG is re-gasified in coastal LNG terminals so that it can be injected into the NG grid. It should be emphasized that both pathways are affected by the fact that the composition of the natural gas transported has high variability.

Figure 1 provides a visual comparison of the volumetric equivalence between diesel, CNG, and LNG for a given energy content.

Figure 1. CNG/ LNG/ Diesel energy and volume equivalence (NGVA Europe).

A well-known practice within the natural gas sector is the addition of odorants to help identify NG in case of a leak. Historically, this has been done in different ways as practically each European country has followed its own national code/standard on this subject. For years, the most used odorants have been tetrahydrothiophene (THT) and mercaptan, both sulfur-based odorants. During the last 10-15 years, several European countries have started to run technical programs in view of the substitution of THT and mercaptans with sulfur-free odorants. Countries like Germany, in which the odorization practice is governed by the DVGW standard G 280-1 ‘Gas Odorization’, started in 1995 developing a sulfur-free odorant for gas distribution networks and, already in 2007 more than 40 gas distributors in Germany, Austria and Switzerland had changed their odorization practices with THT or mercaptans to sulfur-free odorants like Gasodor™ S-Free™. The situation is still not balanced in Europe, however, as there are still countries using THT and mercaptans when running odorization practices. The level of sulfur derived from the addition of THT and mercaptan is linked to the exact positioning of the measurement equipment, as sulfur is more concentrated the closer the measurement is performed to the odorization point. According to E.ON Ruhrgas AG (and though different amounts are used in different countries), these could be indicative values:

- Mean sulfur content before odorization: 3.5–6 mg/m3

- THT is generally adding 5–10 mg/m3 (measured as S)

- Mercaptan is generally adding 1–3 mg/m3 (measured as S)

The use of sulfur-free odorants would mean further reduction of already low sulfur content of natural gas. Sulfur is known for its negative effect on the proper functioning of engine exhaust after-treatment systems leading to reduction of the conversion efficiency over time.

Oil carry-over and water/humidity control at refueling stations

Natural gas refueling stations can either be CNG, LNG, or LCNG stations, which can offer compressed, liquefied or both types of natural gas. LCNG stations are supplied with LNG, and CNG is produced with a vaporizer. Apart from this, CNG stations can either be fed from the natural gas grid directly, or fed from LNG which is then vaporized and put under pressure in order to get it settled to 200 bar. During the compression phase in a natural gas refueling station, some contaminants like water and oil can squeeze into the final compressed gas interfering with the proper functioning of NGVs. Some of the contaminants can come from the grid-distributed gas, and some others, like oil, can come from the compressor lubricants themselves. For those stations directly fed from the grid and also for stations being fed from natural gas mobile storage units, it’s typical that the gas is processed at the refueling site in order to make two main adaptations for its use in the vehicles:

- Drying: NG must be dry enough not to cause corrosion and drivability issues when put under high pressure. Water content values of 5 mg/kg are achievable and are currently good enough to guarantee the proper operation of the vehicles and their systems.

- Filtering: there is no existing suitable method for the measurement of particles in the gas, but for the protection of NGV systems (engines and associated components) it is necessary in order to ensure proper and durable functioning. There are several CNG coalescing filter suppliers that can be used today. According to the suppliers their products are able to remove 99.995% of the aerosols in the size of 0.3 to 0.6 microns when installed in series with other pre-filters. It’s generally recommended to use two filters after the compressor (and before the storage system) and another fine-mesh filter before the CNG dispenser.

Some other factors to consider are: how good are filters in removing aerosols and what is the need to have a proper maintenance program for the filtration systems. Experience has proven that, if not controlled, these two aspects can have important negative effects to the vehicles e.g. in form of corrosion of the CNG metallic tanks. This could affect safety in the long term, drivability problems due to water precipitation in connection with the expansion cooling that occurs when the gas flows from the storage tank to the engine inlet and could create ice plugs, abrasion of the mechanical parts due to solid particles entering the system, oil deposition in the engine’s distribution system, etc.