Compatibility

For using methane as an automotive fuel, the main engine technology to date has been the Otto engine, either under stoichiometric or lean-burn conditions of the air-fuel mixture. Nevertheless other engine technologies have also been developed, such as dual-fuel (DF) engines based on compression-ignition engines. Some of the main differences are as follows:

- Stoichiometric spark-ignition (SI) natural gas engines: characterized by a homogeneous air-fuel mixture, the air-fuel ratio being controlled via an oxygen sensor (or lambda sensor) installed in the exhaust stream.

- Lean-burn spark-ignition NG engines: characterized by a stratified air-fuel mixture. These engines usually require indirect fuel injection or a direct fuel injection with induced turbulence. The indirect fuel injection requires the fuel to be injected in a pre-chamber designed, to keep the air-fuel mixture at stoichiometric conditions until it is suctioned into the combustion chamber. Excess of oxygen concentration in the exhaust is controlled via a linear oxygen sensor.

- Dual-fuel compression-ignition engines using methane and diesel fuel: dual-fuel engines differ from dedicated engines in their capability to burn two fuels at the same time. Dual fuel engines use diesel as the main ignition source for the natural gas-air mixture. Diesel substitution ratios can vary depending on the dual fuel engine technology and also depending on the operation of the engine itself.

High efficiency is achieved with the concepts based on compression ignition (diesel cycle), such as high-pressure direct-injection (HPDI) DF engines for methane and diesel fuel. Spark-ignited methane engines, on an average, have close to 30% higher energy consumption compared to compression ignition engines of the same size and power according to AMF Annex 57 (Söderena et al. 2021). Energy efficiency is higher also for lean-burn engines than for stoichiometric engines. However, energy consumption of methane fuelled cars is lower than that of gasoline fuelled cars (Karlsson et al. 2008).

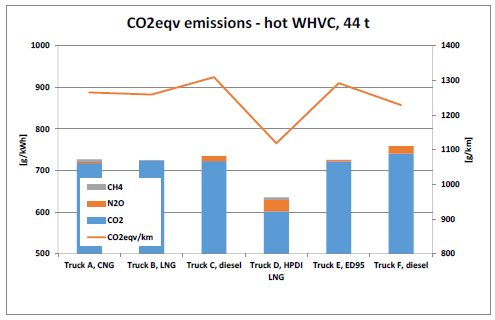

Carbon intensity of methane is better than that of diesel fuel because of the higher hydrogen-carbon ratio of methane (CH4) when compared to diesel (C15H28) or gasoline (C7H15). This generally leads to less or comparable tailpipe CO2 emissions with CNG as for diesel and gasoline engines depending on engine efficiency. This can be seen from the results of the AMF Task 37 (Nylund and Koponen 2012), fuel and technology alternatives for buses were studied, and from a comparison of trucks conducted in the AMF Task 57 (Figure 1). Here it is noted that tailpipe CO2 emissions are only a part of lifecycle greenhouse gas emissions, while methane and nitrous oxide (N2O) emissions are also important.

In AMF Task 55 (Rosenblatt et al., 2020), CNG vehicles showed lower overall CO2 levels of CNG vehicles than comparable gasoline counterparts. In a Swiss measurement campaign, a comparison of two identical (weight, power, transmission type) cars covered one equipped with a CNG engine and one with a gasoline engine.

Figure 1. Trucks using alternative fuels, results from the AMF Task 57. (Söderena et al. 2021).